WE DO STEEL FOUNDRY.

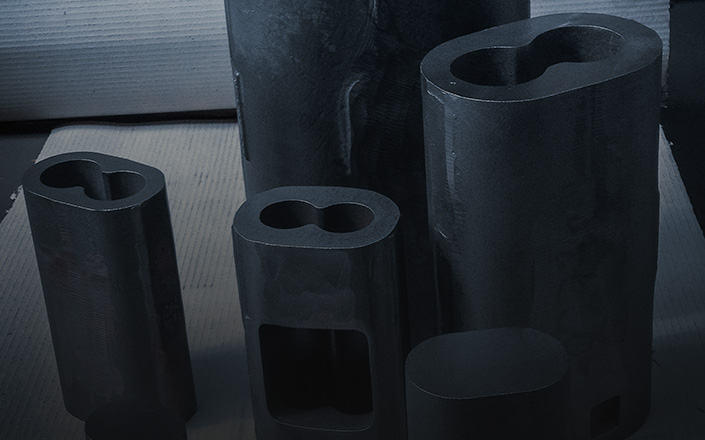

STEEL FOUNDRY HOLLOW MOLD CASTING AND FULL MOLD CASTING

The Steel Foundry division is divided into the areas of hollow mold casting and full mold casting, with the expertise of over 200 recipes. From melting to machining, our stainless steel mold casting offers the best quality in material and design. To reduce foundry waste, we use a special sand system and a closed cycle for raw materials.

WE DO STEEL.

RANGE OF SERVICES AND ADVICE

- Casting technology consulting

- Comprehensive material advice and material development through in-house research & development

- CAD data transfer with casting modification

- Production of Exporit and wood models

- Complete mechanical processing

- Production of raw castings in alloyed or unalloyed cast steel piece weights of up to 12 tons, maximum dimensions 4,800 x 2,400 mm

- Molding processes (full mold casting process, hollow mold casting process, 3D sand printing process)

- Extensive heat treatment options

WE DO INDUSTRY SOLUTIONS.

WE PROVIDE SUPPORT

Our experts provide support with many years of experience and in-depth knowledge. This enables us to find the right decisions for a wide range of requirements. We also offer the right solutions for your industry.

RUST AND ACID RESISTANT

- Turbine and pump industry

- Filtration and centrifuge technology

- Kneading and mixing technology

- Food industry

- Paper and pulp industry

- Power plant technology

- Extruder construction

- General plant engineering

- Hyd…

wear-resistant stainless steel casting

- Straightening, forming and calibrating rollers

- Spinning tools

- Cutting, forming and drawing tools

- Rollers, roller shells

- Die casting systems, extruders

- Pump industry

- Mining, mining industry

- Cement production

- B…

HEAT-RESISTANT CAST STAINLESS STEEL

- Industrial furnace construction

- Sintering plants

- Firing systems

- Hot forming

- Steel industry

- Cement industry

- General power plant and plant engineering

TOOL STEEL CASTING

- Technical casting advice and material advice

- CAD data transfer with casting modification

- Production of Exporit and wood models

- Production of raw castings in alloyed or unalloyed cast steel

- Unit weight up…

WE DO MANUFACTURING.

WE OFFER YOU A WIDE VARIETY OF PRODUCTION FORMS

- Castings up to a delivery weight of 12 tons Induction furnaces (1.0;1.0;2.0;3.5 tons)

- Electric arc furnace (12 tons)

- Plasma ladle furnace

- VOD plant

- Core shooters/core production using hand molds Hand molding lines Box sizes max. 4,500 x 2,200 mm (round: 2,200 mm; square: 3,000 x 3,000 mm)

- 3-D sand printing systems S-MAX

WE DO HEAT TREATMENT.

OUR HEAT TREATMENTS

- Bogie hearth furnaces up to 4,500 x 3,000 x 1,800 mm

- Water basin with counter-current system

- Various vacuum furnaces

- Deep furnaces

- Hood furnaces

WE DO MANUFACTURING.

OUR

POST-PROCESSING

- CNC center lathes up to Ø 1,200 mm

- CNC vertical lathes conventional up to Ø 2,700 mm

- CNC milling machines / conventional boring machines up to 2,000 x 1,600 mm / Ø 1,500 mm

- CNC grinding machines up to Ø 1,000 x 800 mm

- Slotting and drawing machines

- Scanning and measuring equipment

YOUR CONTACT PERSON

Would you like advice, do you have any questions or special requests? - Our specialists are there for you.